New Mesh Welder Speeds Up Production of Welded Wire Retail Projects

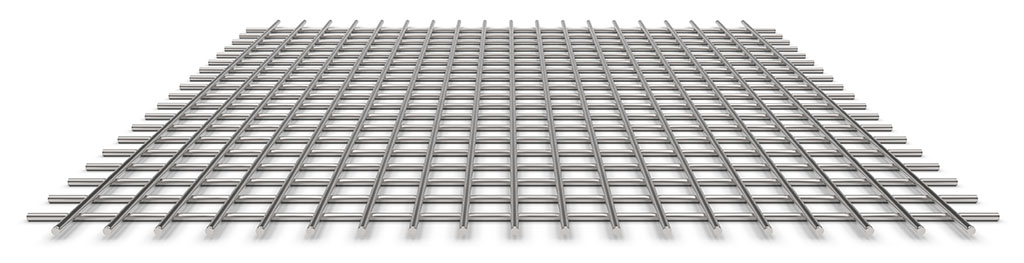

We’re excited about the arrival of our new high-speed mesh welder. Designed to produce high-volume grids, this new equipment increases productivity and efficiency —which in turn speeds up production times of projects requiring welded grid components.

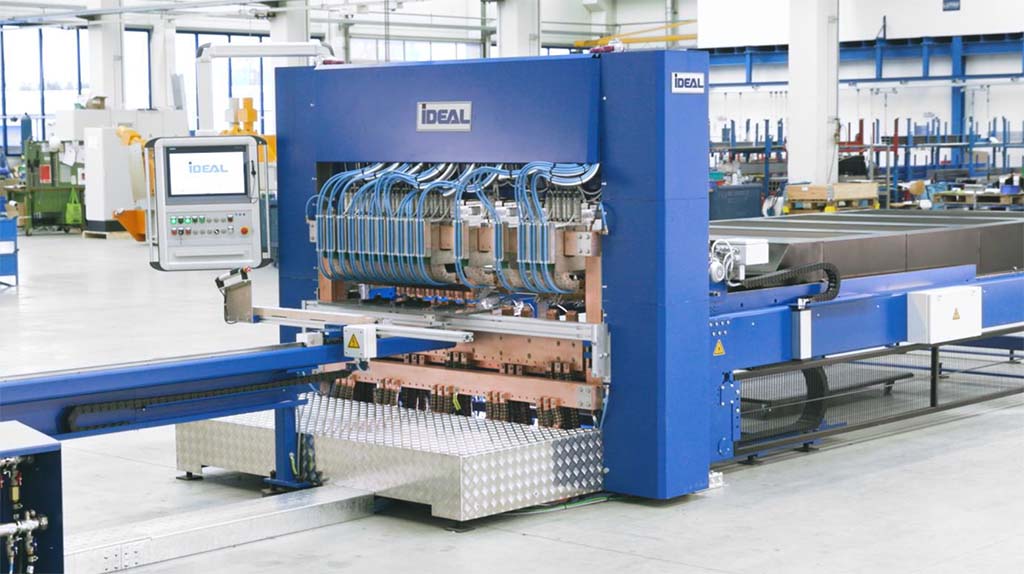

The IDEAL GAM 816 is a high-speed mesh welding machine that is designed for the production of welded wire mesh for various applications. This machine is equipped with several features that make it a top choice for creating products for shelving and decking, protective cages, and more.

And we’re bringing the full slate of its capabilities to your project, meaning you can expect it to be completed to spec and done right the first time. This is one of the advantages of working with McIntyre—we can complete every step of your project under one roof…and the new mesh welder has only enhanced our capabilities.

The IDEAL GAM 816 Enables High-volume Production of Welded Wire Mesh Products

Here are some of the key features of the IDEAL GAM 816:

High-Speed Production for Creating Wire Mesh Retail Displays & Fixtures

One of the most notable features of the IDEAL GAM 816 is its ability to produce welded wire mesh at high speeds.

The machine is capable of producing up to 160 cross wires per minute, which results in a production rate of up to 120 grids per hour. Its high-speed welding process produces 200 strokes per minute. In addition, it features two secondary circuits for a welding process without electrode change. With a toolless easy changeover system, your project can condition moving smoothly through the entire production process.

Automated Operation for Faster Production Times

The IDEAL GAM 816 is designed for automated operation, which means that it requires minimal intervention during production runs.

It also features a high-speed NC drive exit table with pivoting rails and a new switchable welding cylinder Generator 3,5kN/7kN.

Extensive Welding Capabilities for a Variety of Mesh Sizes

The IDEAL GAM 816:

- Can weld mesh from 7.8” – 63” wide.

- Can weld mesh from 19.6” – 137.8” long.

- Weld Wire Diameter from .098” – .315”

- Has an in-line trimming feature to trim grids as they are welded.

Sophisticated User Interface

The IDEAL GAM 816 features a user-friendly interface that makes it easy to set up and operate. The machine is equipped with a touchscreen control panel, which allows operators to adjust the welding parameters and monitor the production process. The interface also provides real-time production data, which helps manufacturers track production and identify any issues that may arise.

McIntyre Displays: Let Us Save You From the Headache of Working With Multiple Vendors

When you’re dealing with multiple vendors, there can be several points of failure throughout the process. However, with McIntyre, you have one single point of contact who will guide you through our entire process. We do everything under one roof, so you don’t have to worry about “farming out” your work to several different vendors.

In the unlikely event something doesn’t go as planned, we’ll be there to fix it—in person—not over the phone or via video call.

Ready to get started? Let us put our new mesh welder to work for you! Contact us today.