Blending creativity, technology, craftsmanship and hard work to build merchandising displays that work for you.

The McIntyre Manufacturing Group blends creativity, technology, craftsmanship, experience and hard work to build displays of all sizes. To control quality and complete jobs on time and within budget we’ve incorporated technology when helpful and relied on tried and tested methods when appropriate.

Specializing in Metal Permanent & Temporary Displays

accented with wood, plastic, lighting and more!

While we specialize in metal, we also utilize and incorporate other materials— such as wood, plastic, and electronics—to provide creative accents that make your display more engaging for customers and more closely aligned with your vision. Our display rack manufacturing operations include:

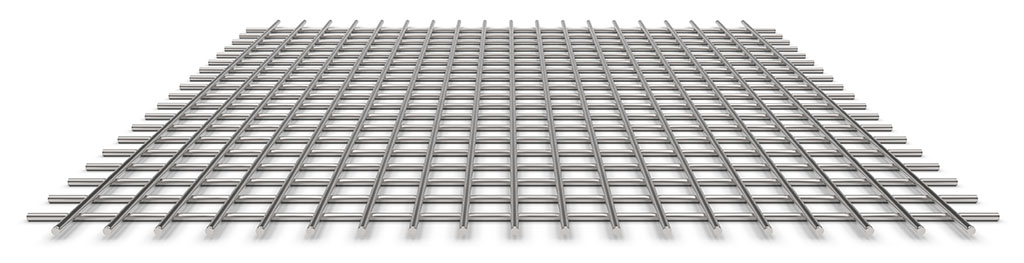

Wire Bending: Grid, Hanger & Other Retail Display Parts

Whether it’s a tool holder, an intricate grid or a wire hanger, we’re able to quickly and accurately manufacture everything you need. Our wire department has multiple CNC-controlled 2D and 3D benders that allow us to bend wire on all three axes. We keep all the parts precise and repeatable. When needed, we can utilize our in-line automatic butt welding capabilities. Because we stock a wide range of materials, we can reduce lead times, and keep your project on time and within budget. Our stock includes bright basic, galvanized and stainless steel.

Fabrication

The foundation of manufacturing is fabrication, the process of shaping, bending and transforming raw materials into usable components. Because we control these manufacturing functions, the McIntyre Manufacturing Group begins every job on time and according to our customer’s expectations. We can manufacture intricate shapes from the simplest laser cut plates to complicated, detailed designs.

Welding: Strong & Sturdy Metal POP Displays

Do you need wire grids or hangers? Our welding department has an extensive variety of services including spot welding, MIG welding, robotic MIG welding and TIG welding. All these welding operations use production-grade fixtures, ensuring consistency, accuracy and a high level of quality. Because our spot welding tips and fixtures are built in-house, we have faster lead times, meaning more efficient production so we can provide our customers with more reasonable prices.

Powder Coating: Reinforcing Your Brand Through Color, Finish & Durability

The McIntyre Manufacturing Group utilizes a sophisticated powder coating system that allows us to match your expectations when it comes to color, finish, and durability of your permanent or temporary retail display. We achieve consistency and precision in our process by utilizing a combination of automatic and manual powder guns and a robust wash system that cleans and pretreats every part. In order to perfectly showcase your brand, we have access to numerous stock colors, can develop a custom powder color, and can offer exact PMS color matching.

Packing, Assembly & Fulfillment

Our staff has experience and a proven success record to deliver your product in the manner you need it, whether it’s being bulk packed or needs the careful the attention of a complicated turnkey project or product rollout, the McIntyre Manufacturing Group can handle it all.

Warehousing & Distribution

We work with our customers to ship finished products exactly how they need it, from a completed, ready-to-display product to knock-down displays. We have extensive relationships with major and small global couriers and LTL & Truckload carriers. This means we can ship products directly to a warehouse, retail center or to a company’s product representatives. McIntyre Manufacturing Group also offers warehousing to help bridge the gap between the due date and when the customer needs product delivered.

Let\’s get started! We\’re ready to answer your questions, give us a call: 336-476-3646.